Why Commercial Buildings Choose V-Bank Filters for Airflow Stability

The Unique V-Shaped Configuration

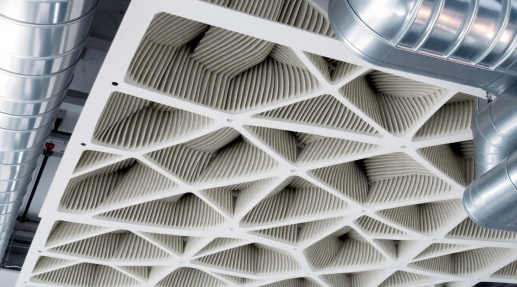

V-bank filters stand out because of their distinctive V-shaped pleat design. This isn’t just for looks; it’s a smart engineering choice. The V-shape allows for a much larger filtration surface area packed into a standard-sized frame. Think of it like folding a piece of paper multiple times to make it fit in a small box – you get more paper surface that way. This increased surface area is key to how these filters perform.

This design means the filter can capture more dust and particles before it gets clogged. It also helps distribute the airflow more evenly across the filter media. This clever configuration is the primary reason V-bank filters are favored for applications needing stable airflow over time. It’s a simple idea with big results for air quality and system efficiency.

Also Read: Geofence Marketing Services Driving Precision in Digital Ad Campaigns

Materials and Construction

When you look at a V-bank filter, you’ll notice it’s built to last and perform. The frame itself can be made from different materials, like sturdy aluminum, galvanized iron, or even durable ABS plastic, which is a good choice for environmental reasons. The filter media inside is usually made from ultra-fine glass fiber paper. This material is chosen because it’s really good at catching tiny particles, typically down to 0.3 microns, with high efficiency.

These filters are often treated to be water-resistant, making them suitable for places with high humidity. The construction aims for a balance: strong enough to handle airflow but delicate enough in its media to trap fine dust. The V-bank structure itself is designed to be robust, supporting the media and maintaining its shape under pressure.

Key Performance Parameters

Several factors define how well a V-bank filter does its job. The MERV rating is a big one, telling you how efficient it is at capturing different particle sizes. Higher MERV ratings mean better filtration. Another important aspect is the initial pressure drop – how much resistance the filter puts up when the air first flows through it. A lower pressure drop is generally better because it means your system doesn’t have to work as hard.

- Filtration Efficiency: How well it captures particles (e.g., MERV rating).

- Pressure Drop: Resistance to airflow.

- Dust Holding Capacity: How much dirt it can hold before needing replacement.

- Airflow Rate: The volume of air it can handle.

These parameters are interconnected. For instance, a filter with a higher efficiency might also have a higher initial pressure drop. The V-bank design aims to optimize these, offering good efficiency with a manageable pressure drop, which is a big deal for long-term performance. Understanding these numbers helps in choosing the right V-bank air filter for any specific job.

Benefits of V-Bank Air Filters for Commercial Applications

Commercial buildings are increasingly turning to V-bank air filters, and for good reason. These filters offer a compelling set of advantages that directly impact building operations and occupant comfort. They aren’t just another component; they’re a smart investment for long-term performance.

Enhanced Airflow Dynamics

The unique V-shaped configuration is the secret sauce here. It dramatically increases the filter media surface area packed into a given space. This means air can flow through more freely, leading to a lower initial pressure drop. This improved airflow is key to preventing strain on HVAC systems. It helps maintain consistent air circulation without the system working overtime, which is a big deal for large commercial spaces.

Extended Filter Lifespan

Because V-bank filters have so much more surface area, they can capture more dust and particulate matter before becoming clogged. This directly translates to a longer service life compared to traditional filters. Think about it: fewer filter changes mean less downtime, less labor, and less waste. This extended lifespan is a major factor in why V-bank filters are preferred for commercial applications where consistent performance is a must.

Reduced Operational Costs

When you combine enhanced airflow with an extended filter lifespan, the result is a significant reduction in operational costs. Lower pressure drop means HVAC fans use less energy to push air through the filters. Fewer filter replacements cut down on material and labor expenses. Over time, these savings add up, making V-bank filters a cost-effective choice for maintaining air quality in commercial buildings. The efficiency of these filters pays dividends.

Maintaining Performance in Diverse Environments

Resistance to High Humidity

V-bank filters are built to handle more than just dry air. In humid conditions, the filter media can absorb moisture. This absorption can lead to a few issues. First, it might make the media swell, which increases the resistance to airflow. This means your HVAC system has to work harder, using more energy. Second, prolonged exposure to moisture can degrade certain filter materials over time, shortening their lifespan. Choosing V-bank filters with media specifically designed for high-humidity environments is key to preventing these problems. These filters often use synthetic materials that don’t absorb as much water, maintaining their structural integrity and filtration efficiency even when things get steamy.

Impact of Temperature Variations

Temperature swings can also play a role in how well V-bank filters perform. Extreme heat can cause some filter materials to break down faster, reducing their effectiveness and potentially releasing particles into the air. On the flip side, very cold temperatures can make certain media brittle, leading to cracks or tears. This compromises the filter’s ability to capture contaminants. For applications where temperature is a major concern, selecting V-bank filters with robust media that can withstand a wide temperature range is important. This ensures consistent airflow and filtration, no matter the season.

Suitability for Critical Environments

Because of their robust construction and ability to maintain airflow, V-bank filters are often found in sensitive areas. Think data centers, hospitals, or cleanrooms. In these places, consistent air quality and stable airflow are not just about comfort; they’re about protecting expensive equipment or patient health. The V-bank’s design helps prevent premature clogging, which is a big deal when you can’t afford downtime or contamination. This makes them a reliable choice for environments where performance cannot be compromised. The durability of these filters in varied conditions is a major selling point.

V-Bank Air Filters in Action

Applications in High-Cleanliness Settings

V-bank filters are a go-to choice for places that need really clean air. Think about places making computer chips, or where food is processed, or even hospitals. These spots can’t afford to have tiny particles floating around. The V-bank design helps capture a lot of this stuff, keeping the air pure. It’s all about making sure the air quality is top-notch for sensitive processes and people.

Role in Industrial Air Intake Systems

In big factories, machines like gas turbines and air compressors need clean air to work right. If dirty air gets sucked in, it can damage the equipment and mess up the whole operation. V-bank filters act as a strong first line of defense, filtering out dust and debris before it can cause problems. This keeps expensive machinery running smoothly and prevents costly breakdowns. It’s a smart way to protect valuable industrial assets.

Use in HVAC and Air Purification

Beyond specialized areas, V-bank filters are common in everyday HVAC systems and air purifiers. They help make the air in offices and commercial buildings healthier to breathe. By trapping common pollutants like dust, pollen, and mold spores, these filters contribute to a more comfortable and productive environment for everyone. Their ability to handle a lot of air without getting clogged too quickly makes them a practical choice for these widespread applications. The airflow they provide is consistent, which is key for system efficiency.

Long-Term Airflow Stability

Maximizing Filtration Surface Area

V-bank filters are designed with a unique V-shaped configuration. This structure significantly increases the available filtration surface area compared to flat panel filters. More surface area means the filter can capture more particles before becoming clogged. This directly contributes to long-term airflow stability because the air has more pathways to travel through. It’s like having a wider road for traffic – less congestion, smoother flow. This design helps maintain consistent airflow even as the filter collects dust and debris over time.

Minimizing Pressure Drop Over Time

The V-shaped pleats aren’t just about more surface area; they also optimize how air moves. This design creates channels that reduce resistance. As a result, the pressure drop across the filter stays lower for longer. A lower pressure drop means the fan doesn’t have to work as hard, saving energy and reducing wear and tear. This consistent, low pressure drop is key to maintaining stable airflow throughout the filter’s service life. It prevents the common issue where filters become restrictive, forcing systems to compensate and potentially leading to reduced performance elsewhere.

Consistent Performance Through Service Life

When a filter maintains its airflow characteristics, the entire HVAC system operates more predictably. V-bank filters are built to resist clogging and maintain their structural integrity. This means the airflow you get when the filter is new is very similar to the airflow you get months later, just before replacement. This predictability is vital for commercial buildings where consistent air quality and system efficiency are paramount. The long-term airflow stability provided by V-bank filters translates to reliable operation and fewer unexpected maintenance issues, making them a smart choice for demanding environments.

Choosing the Right V-Bank Air Filter

MERV Ratings and Efficiency

When you’re looking at V-bank filters, the first thing you’ll probably see is the MERV rating. This number tells you how good the filter is at catching different sizes of particles. Higher MERV ratings mean better filtration, which is great for sensitive environments. But, a higher MERV rating can also mean more resistance to airflow. It’s a balancing act. You need to pick a MERV rating that cleans the air well enough for your needs without making your system work too hard. For example, a MERV 13 filter is a solid choice for many commercial buildings, catching things like bacteria and smaller dust particles. A MERV 15 or 16 filter will catch even finer stuff, like smoke and viruses, but it will also increase the pressure drop more.

It’s important to match the MERV rating to your specific application. Don’t just go for the highest number available. Think about what you’re trying to filter out and what your HVAC system can handle. A filter that’s too restrictive can strain your equipment and use more energy. We’ve seen systems struggle with filters that were just too much for them. So, check the specs and talk to an expert if you’re not sure. Getting this right from the start saves a lot of headaches later on.

Here’s a quick look at what different MERV ratings generally capture:

| MERV Rating | Particle Size Captured (Microns) | Common Applications |

| 1-4 | >10 | Basic dust, lint |

| 5-8 | 3-10 | Pollen, mold spores, dust mites |

| 9-12 | 1-3 | Bacteria, auto emissions, humidifier dust |

| 13-16 | 0.3-1 | Smoke, viruses, sneeze nuclei |

| 17-20 | <0.3 | HEPA-level filtration (specific applications) |

| 17-20 | <0.3 | HEPA-level filtration (specific applications) |

Frame and Filter Media Options

Beyond the MERV rating, the materials used in a V-bank filter matter a lot. The frame, often made of sturdy plastic or metal, needs to be robust enough to handle the air pressure and the environment. Some frames are designed for easy handling and installation, which is a nice bonus during maintenance. The filter media itself is where the real magic happens. You’ll find options like synthetic fibers, which are great because they don’t break down easily and can handle moisture pretty well. This is a big deal if your building has high humidity.

Some V-bank filters use media treated to be waterproof, making them ideal for places like food processing plants or areas prone to dampness. Others might use materials that are more resistant to high temperatures. If your system runs hot, you’ll want to look at media that won’t degrade. The choice of media directly affects how long the filter lasts and how well it performs over time. A good V-bank filter will use media that balances filtration efficiency with durability.

Consider these points when looking at frames and media:

- Frame Material: ABS plastic is common for its durability and light weight. Galvanized steel offers more rigidity for demanding applications.

- Media Type: Synthetic fibers (polyester, polypropylene) are popular for their moisture resistance and consistent performance.

- Special Treatments: Look for media that’s water-repellent or has enhanced heat resistance if your environment requires it.

Considering Specific Application Needs

Every building is different, and so are its air filtration needs. A hospital’s operating room has vastly different requirements than a warehouse. For places that need super clean air, like semiconductor manufacturing or pharmaceutical production, you’ll need V-bank filters with very high MERV ratings and specialized media. These filters are designed to capture the tiniest particles that could ruin a product or compromise a sterile environment. The V-bank design helps here by packing a lot of filter surface area into a small space, which is good for systems where room is tight.

Think about the conditions the filter will face. Is it going to be exposed to high humidity? Will temperatures fluctuate wildly? Some V-bank filters are built tough to handle these challenges. For instance, filters designed for industrial air intake systems need to be robust and able to handle large volumes of air, often with a lot of dust or contaminants. Choosing the right V-bank filter means looking at the whole picture: the air quality goals, the environmental conditions, and the capabilities of your existing HVAC system. It’s not just about buying a filter; it’s about finding the best solution for long-term airflow stability and air purity.

Selecting the correct V-bank filter involves a careful assessment of both the required filtration level and the operational environment. This ensures optimal performance and longevity.

Wrapping Up: Why V-Bank Filters Stick Around

So, when you look at it all, V-bank filters just make sense for buildings that need air to flow steady over the long haul. They handle more dirt without getting all clogged up, which means less work for the HVAC system and lower energy bills. Plus, they hold up better in different conditions, even when things get a bit damp. It’s not really a surprise that so many places rely on them to keep the air clean and the systems running smoothly year after year. They’re a solid choice for stable, efficient air handling.