Foam Conversion: Shaping Everyday Bespoke Acoustic Solutions

Introduction

When you sit on a comfortable sofa, enjoy clear audio in a cinema, or notice the quiet hum inside a vehicle, you may not realize that foam plays a crucial role in making those experiences possible. Through a process called foam conversion, raw foam is transformed into products that enhance comfort, reduce noise, and improve insulation.

But foam conversion is not only about shaping cushions or packaging—it is also about developing bespoke acoustics that solve complex challenges across industries. From recording studios to marine engine rooms, acoustic foam is helping create quieter, more efficient environments.

This article explores how foam conversion works, why bespoke acoustics are important, and how these solutions influence both daily life and advanced industries.

1. Understanding Foam Conversion in Simple Terms

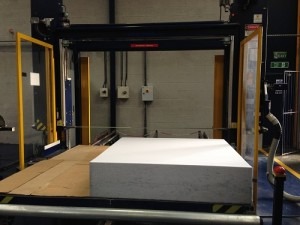

At its core, foam conversion means taking foam in its raw block or sheet form and processing it into a finished product that meets a specific need. Think of it like tailoring a piece of cloth: the material is the same, but the design, cut, and stitching make it suitable for different purposes.

Some foams used in conversion include:

- Polyurethane foam – common in furniture, bedding, and insulation.

- Polystyrene foam – lightweight and insulating, ideal for packaging and construction.

- Polyethylene foam – strong, moisture-resistant, often used for padding and protective cases.

Conversion techniques range from simple cutting into sheets to advanced computer-controlled profiling for complex designs such as acoustic panels.

2. Everyday Benefits of Foam Conversion

While foam conversion often sounds like an industrial process, its results are deeply present in daily life.

- Home Comfort: The cushions on your sofa, the mattress you sleep on, and even the insulation in your walls often come from converted foam.

- Entertainment: Bespoke acoustic panels made through conversion ensure crisp sound in cinemas, home theaters, and recording studios.

- Workplaces: Offices use acoustic foam to reduce noise distractions and improve communication clarity.

- Travel: Car seats, headrests, and interior panels all rely on foam conversion for comfort and noise control.

- Healthcare: From wheelchair cushions to orthopaedic supports, converted foam products provide safety and comfort to patients.

Without foam conversion, everyday experiences would be noisier, less comfortable, and less efficient.

3. Bespoke Acoustics: Tailored Sound Control

One of the most exciting outcomes of foam conversion is the creation of bespoke acoustics. Unlike generic soundproofing, bespoke acoustics are tailored to the specific challenges of a room, vehicle, or environment.

For example:

- A recording studio may need pyramid-shaped foam panels to absorb echoes and provide clean audio.

- A restaurant may require discreet wall panels to reduce background noise and improve customer comfort.

- A marine yacht engine room needs specialized foam to withstand moisture while reducing vibration and noise.

- In construction vehicles, foam is designed to manage sound around radiators and engines where standard insulation is ineffective.

This customization ensures that the solution fits the space perfectly, providing not just sound absorption but also better energy efficiency and durability.

4. Innovation in Foam Conversion

The industry has come a long way since foam was simply cut into sheets. Today, advanced technology is driving innovation:

- CNC Profiling Machines allow detailed, computer-controlled designs for complex acoustic shapes.

- Water Jet Cutting delivers precise cuts without damaging the foam’s structure.

- Laminating combines layers of foam or other materials for enhanced properties.

- Spray Booth Coatings add protective or acoustic finishes, making foam suitable for harsher environments.

These technologies mean foam conversion is no longer limited to standard products but can deliver advanced, technical solutions across multiple sectors.

5. Environmental Responsibility in Foam Solutions

Sustainability is becoming an important part of modern foam conversion. Many companies now offer:

- Recycled foams to reduce waste.

- Eco-friendly materials that maintain performance while lowering environmental impact.

- Efficient processes that minimize energy consumption during production.

This balance between performance and environmental responsibility ensures foam conversion remains relevant in industries moving toward greener practices.

6. Key Industries Using Foam Conversion

Different industries rely on foam conversion in unique ways. Some notable sectors include:

- Automotive – seats, dashboards, insulation, and soundproofing.

- Construction – thermal and acoustic insulation for walls, ceilings, and flooring.

- Marine and Aerospace – lightweight, moisture-resistant acoustic foams for cabins and engine rooms.

- Medical – cushions, braces, and medical packaging.

- Electronics and Packaging – protective foam inserts for delicate equipment.

In each case, foam conversion is customized to meet the sector’s needs, whether it’s durability, comfort, or precise sound absorption.

7. Benefits of Bespoke Foam Solutions

The advantages of foam conversion and bespoke acoustics go beyond simple noise control. They include:

- Personalisation – tailored solutions that match the exact dimensions and requirements of a project.

- Noise Reduction – effective sound absorption that creates better living and working conditions.

- Comfort Enhancement – improved seating and cushioning in homes, vehicles, and workplaces.

- Durability – materials engineered to withstand moisture, heat, or heavy use.

- Improved Safety – protective packaging and medical foam reduce risks of damage and injury.

- Cost-Effectiveness – customized foam products reduce waste and increase efficiency in production.

8. Looking Ahead: The Future of Foam Conversion

As industries evolve, so too will the demand for advanced foam solutions. Future developments may include:

- Smarter acoustic panels designed with AI-driven modelling for maximum efficiency.

- Greater use of recycled foams to promote circular economies.

- Multi-functional foams that combine acoustic, thermal, and fire-resistant properties in a single product.

This innovation will push foam conversion further into everyday life, offering not just comfort and sound control but also environmental benefits.

Conclusion

Foam may appear simple, but through foam conversion, it becomes a powerful tool that improves comfort, safety, and acoustic quality in our lives. From bespoke acoustic panels in studios and restaurants to foam seats in cars and insulation in homes, its presence is everywhere.

By combining advanced technology with sustainable practices, foam conversion ensures that industries can continue to innovate while meeting the growing demand for customized, efficient solutions.

In short, foam conversion is not just about shaping a material—it’s about shaping better environments for living, working, and enjoying everyday life.